Fiber Established Plastic-type material (FRP) has transformed a number of sectors, supplying a lightweight, resilient, and functional replacement for classic supplies like metallic and hardwood. FRP manufacturers enjoy a crucial role in bringing these innovative components to promote, serving different sectors ranging from aerospace and car to development and facilities. Here’s a thorough help guide everything you should learn about FRP manufacturers.

Substance Expertise: fiber reinforced plastic specialize in making composite supplies making use of a mixture of high-durability fabric such as fiberglass, carbon dioxide, or aramid, embedded in a resin matrix. This expertise ensures the production of FRP components with precise technical properties personalized to meet the criteria of diverse programs.

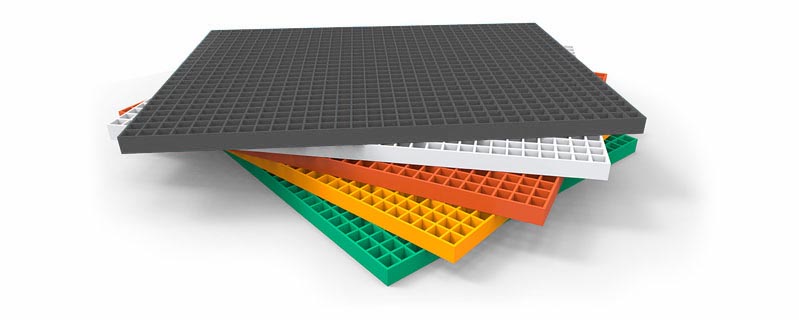

Changes: One of many crucial strong points of FRP manufacturers depends on remarkable ability to customize products based on buyer specifications. No matter if it’s the measurements, power, colour, or surface finish off, manufacturers can tailor FRP methods to fit specific undertaking requires, providing versatility unrivaled by other materials.

Quality Assurance: Established FRP manufacturers abide by strict high quality manage procedures throughout the production process. From raw materials selection to closing inspection, every step is meticulously watched to ensure regularity and reliability inside the finished items.

Advancement and R&D: Top FRP manufacturers make investments heavily in investigation and development to keep ahead of the curve. This resolve for development drives the development of new resources, producing methods, and programs, pushing the boundaries of the things is feasible with FRP.

Ecological Sustainability: A lot of FRP manufacturers prioritize sustainability, utilizing eco-pleasant resins and including trying to recycle campaigns into their functions. By minimizing squander and decreasing ecological impact, these manufacturers play a role in a far more lasting long term.

App Diversity: FRP manufacturers cater to a wide array of businesses and applications. From lightweight factors for plane and autos to rust-tolerant components for chemical substance finalizing plants and flowers and offshore systems, FRP discovers software in diversified market sectors due to its extraordinary attributes.

Collaborative Partnerships: FRP manufacturers often team up with technicians, architects, and makers to develop impressive remedies for complicated problems. By encouraging relationships and using combined experience, manufacturers make sure the effective incorporation of FRP materials into varied assignments.

In summary, FRP manufacturers enjoy a vital position in driving a vehicle innovation and providing great-performance components across various sectors. Because of their expertise, modification capabilities, and dedication to quality and sustainability, they still form the way forward for modern engineering and construction.